Stay up to date with notifications from The?Independent

Notifications can be managed in browser preferences.

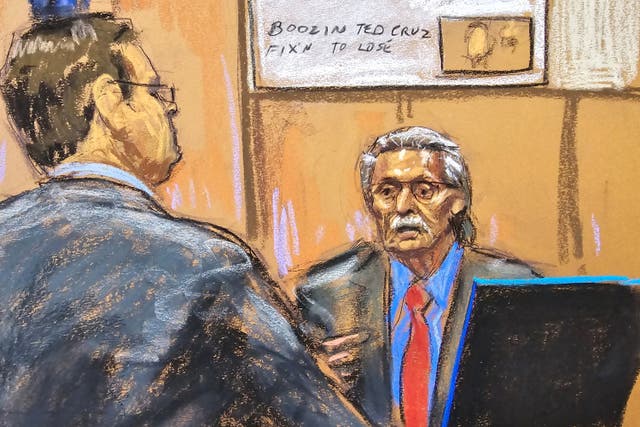

Campus protests

Trump on trial

Top stories

‘That’s crap’: Republican Senators on Caitlin Clark’s WNBA salary

‘I don’t think there’ll ever be too many women athletes who will make like the stars,’ said Senator Tommy Tuberville

‘That’s crap’: Republican Senators on Caitlin Clark’s WNBA salary

‘I don’t think there’ll ever be too many women athletes who will make like the stars,’ said Senator Tommy Tuberville

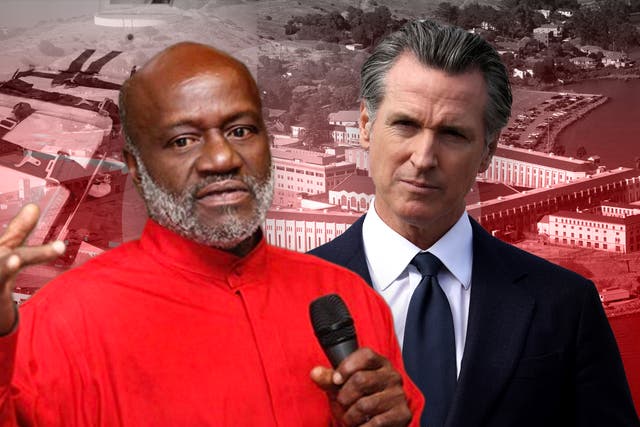

Will a state court challenge end California’s death row for good?

California has more people on death row than any other state in the country — and a governor who opposes capital punishment. A new audacious legal challenge to the death penalty in the state supreme court is seeking to finally end executions forever, Josh Marcus reports

Will a state court challenge end California’s death row for good?

California has more people on death row than any other state in the country — and a governor who opposes capital punishment. A new audacious legal challenge to the death penalty in the state supreme court is seeking to finally end executions forever, Josh Marcus reports

Lifestyle

How young is too young to learn about sex?

Olivia Rodrigo’s team reportedly stopped abortion funds from distributing free emergency contraceptives on tour because her audience was deemed ‘too young’ to receive such items. According to sex education advocacy groups that spoke to Meredith Clark, this misconception is just one of many barriers toward a quality education

How young is too young to learn about sex?

Olivia Rodrigo’s team reportedly stopped abortion funds from distributing free emergency contraceptives on tour because her audience was deemed ‘too young’ to receive such items. According to sex education advocacy groups that spoke to Meredith Clark, this misconception is just one of many barriers toward a quality education